CNC İşleme

OUR SERVICES

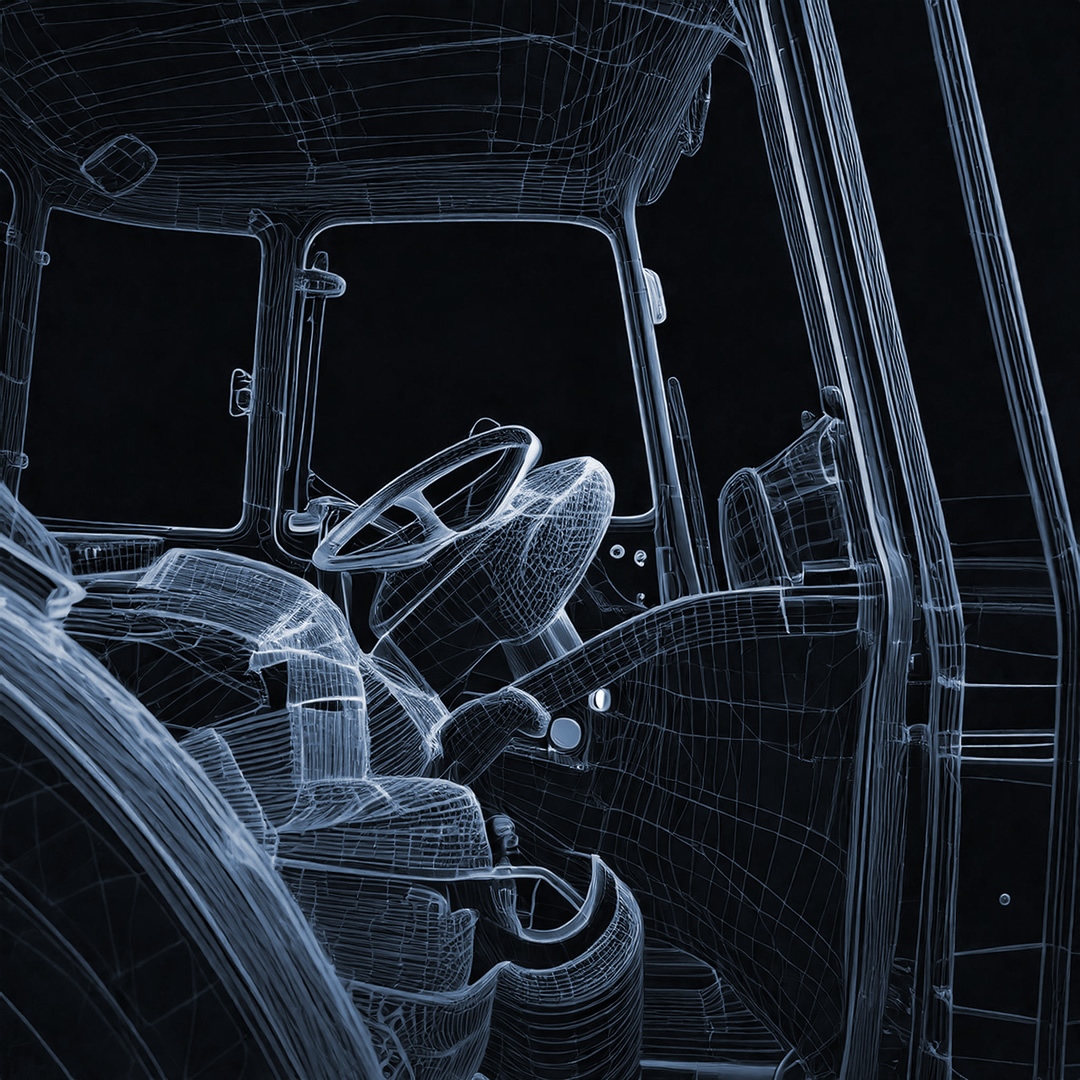

High-Precision Solutions for Thermoforming Vacuum Production ProcessesWe support our expertise in thermoforming plastic production with our powerful CNC infrastructure. The 3-axis and 5-axis CNC machining centers in our facility provide high precision, repeatability, and flexibility in both aluminum mold production and part machining processes. Our CNC capabilities, from vacuum molds, model machining, plastic part cutting, to technical part production, are designed to optimize every step of the process.

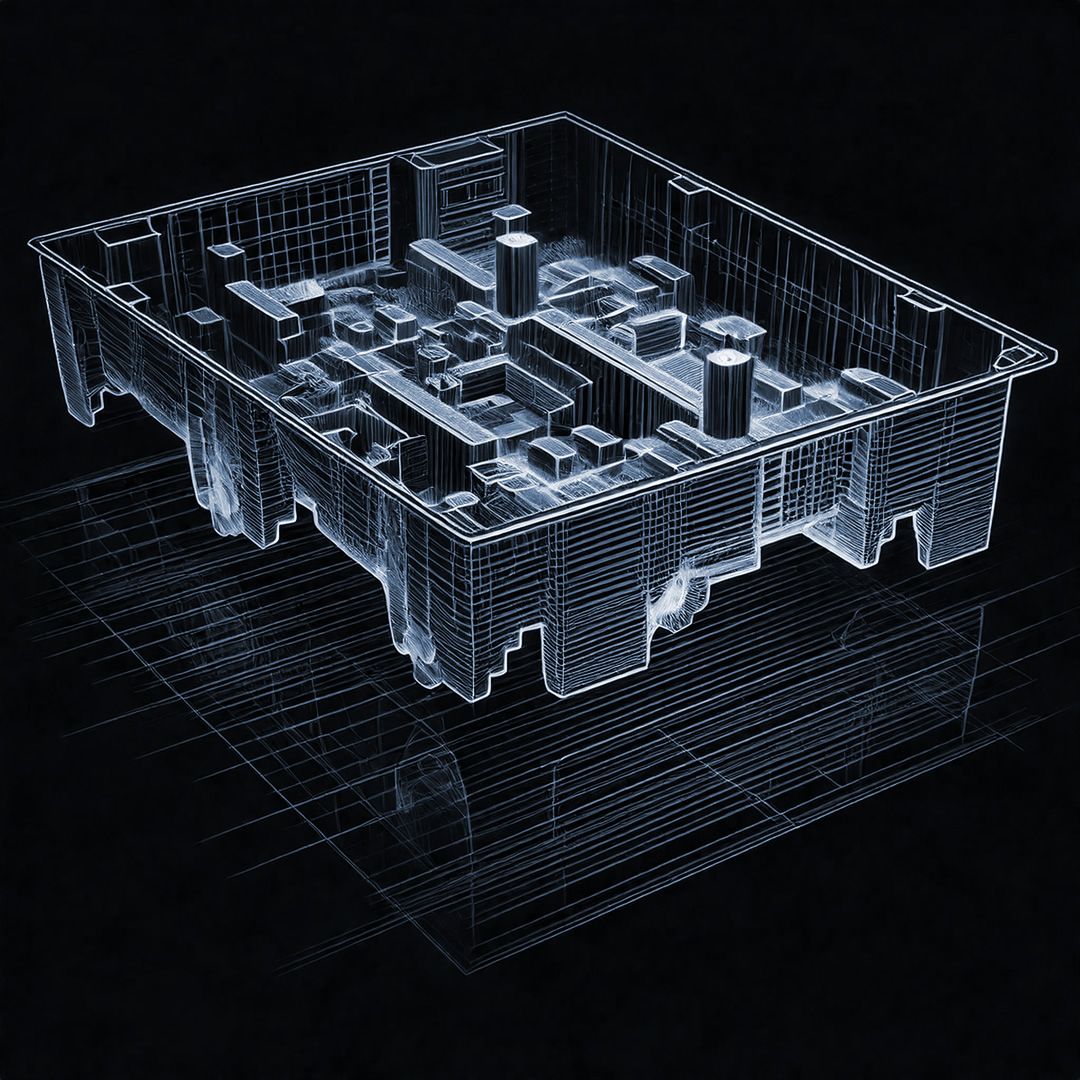

Aluminum Mold MachiningAluminum vacuum molds, which form the foundation of thermoforming quality, are machined on 3-axis CNC machines within our company. For molds with complex surface geometries:

•High surface quality

• Proper thickness and homogeneity for thermal balance and long-term durability

• Precise dimensional tolerances

• Production-ready mold design;“Optimal mold design is achieved by analyzing material homogeneity, thinning, and stresses using simulation tools such as Ansys Polyflow. “We produce ready-to-use, long-lasting molds for your thermoforming line.

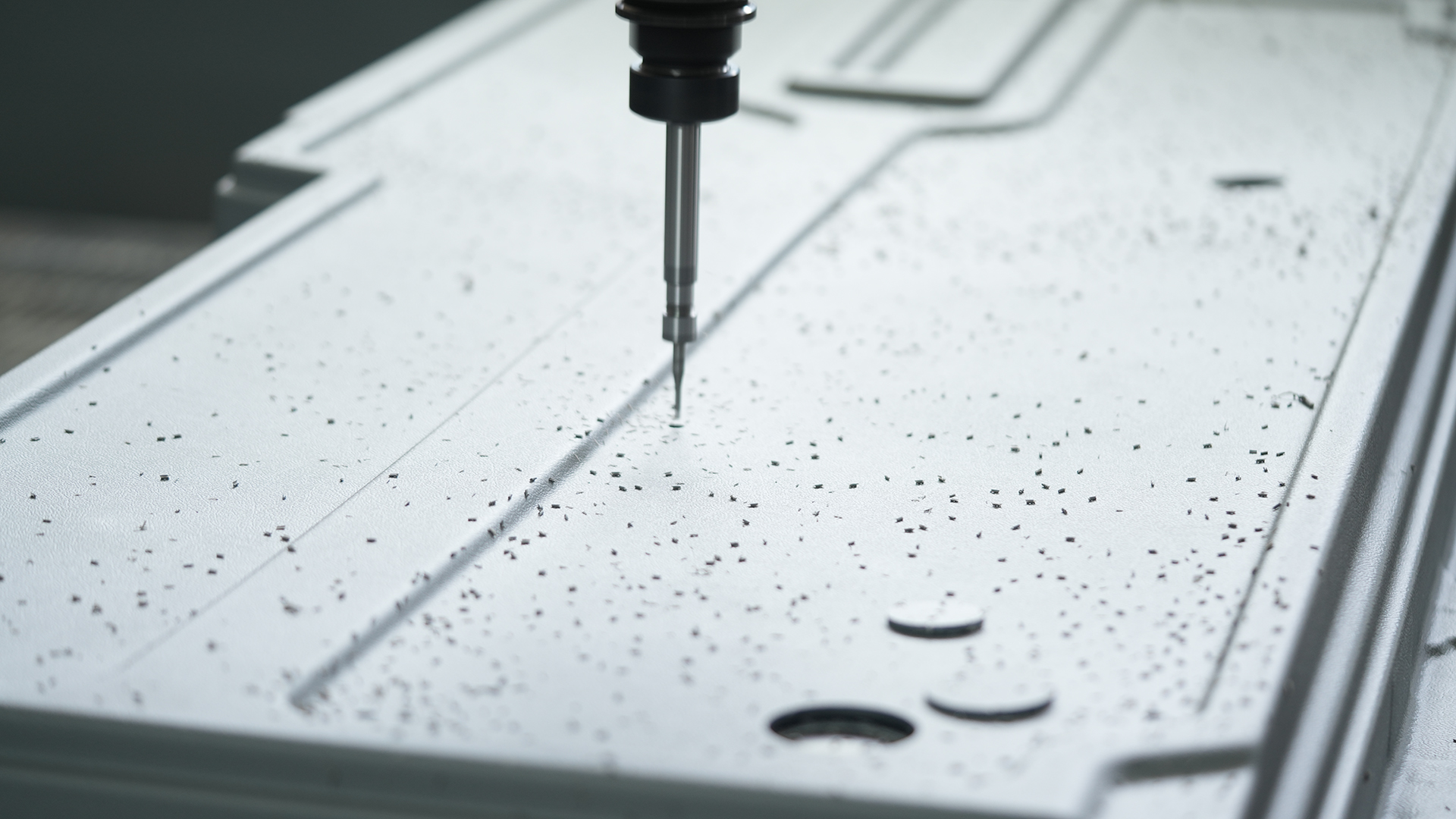

Plastic Part Cutting – CNC-Supported Finishing OperationsCutting, drilling, and contouring operations on plastic parts after thermoforming are performed using CNC-controlled special fixture systems. Especially for large and precise parts:

• Contour edge cutting

• Drilling of screw, assembly, and connection areas

• Window and opening cutting

• Final finishing of parts removed from the moldWe provide these services comprehensively.

-Technical Plastic Part Processing (Delrin, ABS, PVC, PP, PE...) We also produce custom parts from engineering plastics using our CNC infrastructure. Technical plastics such as Delrin, ABS, PE, PVC, and similar materials are processed with high precision for structural parts and components beyond thermoforming. Application areas:

• Connection fixtures

• Custom adapter parts

• Mounting elements

• Machine parts and prototypes

• Variations of injection-molded parts.

Model Processing – Styrofoam & MDF Model ProductionWe offer high-volume processing services for pre-mold volumetric designs, mold models, and presentation prototypes using model materials such as styrofoam (EPS/XPS) and MDF. Our advantages:

• Fast production

• High detail on complex surfaces

• Excellent surface preparation for sanding and coating

• Ideal solutions in terms of cost-effectiveness

The Entire Process Under One Roof – Fully Integrated ProductionOur CNC machining processes are fully integrated with our R&D and design teams. By managing the entire chain from design to mold, and from mold to part, under one roof:

• Simplifies process tracking

• Shortens delivery times

• Ensures quality

• Reduces external dependency

CNC Solutions Empowering the IndustryWith our specialized mold and part processing capabilities for thermoforming vacuum production, we offer customized, fast, and precise solutions for every project.

Aluminum Mold MachiningAluminum vacuum molds, which form the foundation of thermoforming quality, are machined on 3-axis CNC machines within our company. For molds with complex surface geometries:

•High surface quality

• Proper thickness and homogeneity for thermal balance and long-term durability

• Precise dimensional tolerances

• Production-ready mold design;“Optimal mold design is achieved by analyzing material homogeneity, thinning, and stresses using simulation tools such as Ansys Polyflow. “We produce ready-to-use, long-lasting molds for your thermoforming line.

Plastic Part Cutting – CNC-Supported Finishing OperationsCutting, drilling, and contouring operations on plastic parts after thermoforming are performed using CNC-controlled special fixture systems. Especially for large and precise parts:

• Contour edge cutting

• Drilling of screw, assembly, and connection areas

• Window and opening cutting

• Final finishing of parts removed from the moldWe provide these services comprehensively.

-Technical Plastic Part Processing (Delrin, ABS, PVC, PP, PE...) We also produce custom parts from engineering plastics using our CNC infrastructure. Technical plastics such as Delrin, ABS, PE, PVC, and similar materials are processed with high precision for structural parts and components beyond thermoforming. Application areas:

• Connection fixtures

• Custom adapter parts

• Mounting elements

• Machine parts and prototypes

• Variations of injection-molded parts.

Model Processing – Styrofoam & MDF Model ProductionWe offer high-volume processing services for pre-mold volumetric designs, mold models, and presentation prototypes using model materials such as styrofoam (EPS/XPS) and MDF. Our advantages:

• Fast production

• High detail on complex surfaces

• Excellent surface preparation for sanding and coating

• Ideal solutions in terms of cost-effectiveness

The Entire Process Under One Roof – Fully Integrated ProductionOur CNC machining processes are fully integrated with our R&D and design teams. By managing the entire chain from design to mold, and from mold to part, under one roof:

• Simplifies process tracking

• Shortens delivery times

• Ensures quality

• Reduces external dependency

CNC Solutions Empowering the IndustryWith our specialized mold and part processing capabilities for thermoforming vacuum production, we offer customized, fast, and precise solutions for every project.